Let us introduce you to a cotton boll. Boll, that is, not ball. The fluffy, white stuff inside the boll, or hull, is used to make the jeans you wear. If you look at the white stuff with a hand lens, you will see short, silky fibers. You can’t see the sticky seeds inside the fiber, but when you try to remove them, you’ll know seeds well.

Cotton was the main crop at the Shields-Ethridge Heritage Farm after the Civil War. Textile mills bought cotton and spun it into cloth. It would take about 360 bolls like this one to make a pair of jeans.

Planting, cultivating, and picking cotton was hard work, and the whole family helped. Cotton seed was planted in April, after the fields had been plowed. As the plants grew, they had to be thinned, or “chopped.” Plants were also fertilized to help them grow. They were also “mopped” with insecticide to keep the boll weevil away. The boll weevil was a beetle that burrowed inside the boll and destroyed it.

|

Farmers called the boll weevil, the “winged devil.” |

The bolls were picked and placed on a cotton sheet. The sheets were taken by wagon to the gin, where the seeds were removed. Before Eli Whitney invented the cotton gin, seeds were removed by hand. When you visit the Shields-Ethridge Farm, you’ll see how long it takes to remove anywhere from 12 to 42 seeds from each boll. It might take a whole day to “gin” a pound of cotton by hand. With the first cotton gin, hand-cranked, 50 pounds of cotton could be ginned in a day. Ira Ethridge’s cotton gin, powered by a steam boiler and engine, ginned 500 pounds of cotton in 21 minutes!

The “through and through” gin that you will see at the Shields-Ethridge Farm could process cotton from wagon to finished bale in one process. Ira Ethridge was very proud of the Lummus gin he purchased. Neighbors brought their cotton to the Ethridge gin to be processed. Wagons, loaded with “seed cotton” waited their turn at the gin.

When it was his turn, the driver pulled his wagon onto the scale, to weigh both wagon and cotton. The weighing was repeated when the wagon was empty, to find out how many pounds of cotton had been delivered.

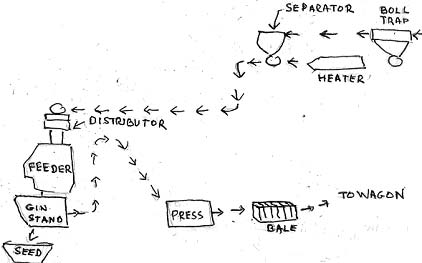

After weighing, a suction tube brought the seed cotton inside the gin. First, a “boll trap” removed bolls that were green (not ripe), rocks, or other hard materials from the cotton. Then the cotton was pulled to a separator, where it dropped onto a sealed conveyer belt that carried the cotton to a “distributor” above a gin stand. Inside the gin stand were 80 “saws.” A cylinder with rows of teeth (saws) turned against another with stiff wire brushes. The cotton was pulled through the metal teeth, leaving the seed behind. The wire brushes swept the fibers away from the teeth. The cotton seed fell into a basket beneath the gin stand and was either sold to Ira Ethridge and sent to his seed house, or was saved for the farmer to pick up at the “seed drop.” The lint was sent to the bale press, where the lint was squeezed into 500 pound bales, wrapped with brown cloth, and tied with metal straps about two inches wide. The bale was sent to the loading platform, where the farmer was waiting with the wagon.

Follow the diagram below to understand the cotton ginning process, as well as to imagine the noise and dust at the gin! Imagine the wagon, loaded with seed cotton, to the upper right of the diagram. Then imagine the wagon pulling up to the loading dock to receive a cotton bale that as large as a refrigerator!

For every 1500 pounds of seed cotton, 500 pounds of “lint” (which would be spun into cloth) and 800 pounds of seed was collected. The rest of the 1500 pounds was trash and moisture. Farmers in the area could pay for ginning services at the Ethridge gin, but they usually gave a portion of their seed to the ginner. The ginner sold the seed to a local cottonseed oil mill. Cotton seed oil was used for cooking, as well as an ingredient in soap, insecticide, and cosmetics.

Here is a photograph, taken in 1920, of workers at the Ethridge gin. They are standing in front of the gin stands, waiting for the seed and lint. The Ethridge gin was a three 80 saw gin. Do you know what that means, after studying the diagram of the ginning process?

Take a look at the map of the Shields-Ethridge Farm again. Notice the location of the cotton seed house, the gin, and the water tower. What do you think is the reason for their location? Do you think you could find the road where wagons waited with their cotton when you visit the Farm?

Student Activity

Fixing a Gin

After you have visited the Shields-Ethridge Heritage Farm and have seen the gin, you might want to try fixing a hand gin, a lesson provided by the Smithsonian Institute.

Fixing a Gin: Math and History at Your Desk